Indian Point Decommissioning

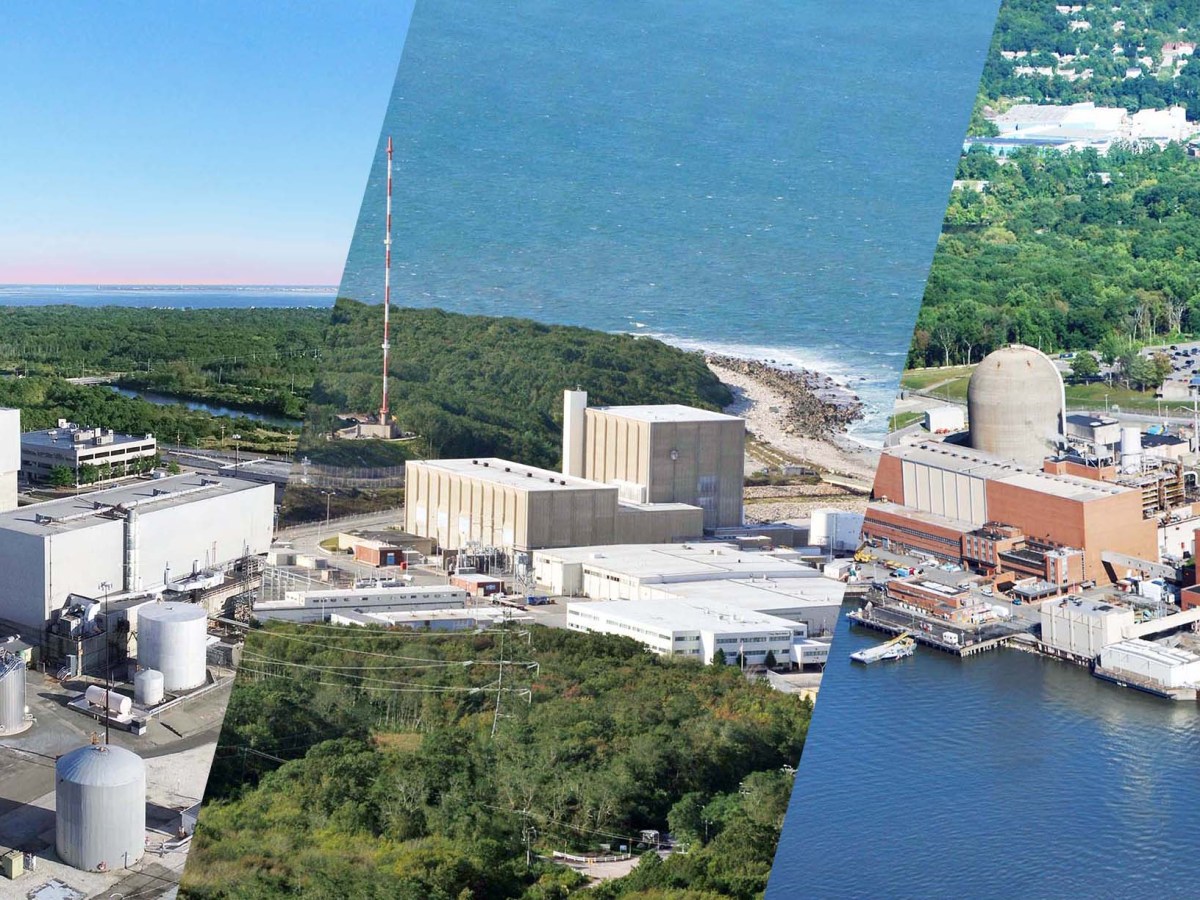

Indian Point Energy Center was shut down permanently by Entergy on April 30, 2021, after providing electricity safely to the region for nearly 60 years. In May of 2021, Indian Point Energy Center was purchased by Holtec International in a deal that allowed the site to enter immediate decommissioning. The deal enables decommissioning and site release for alternate uses decades sooner than previously anticipated. As Indian Point enters into this new chapter, its commitment to safety, the community and the environment remains unchanged.

Our Goals for Decommissioning Indian Point

Achieving excellence in the health and safety of personnel

Protecting the environment now and for future generations

Ensuring a safe, respectful and equal opportunity workplace

Demanding the highest level of individual and corporate integrity

Continually improving upon our robust quality assurance program

Employing financially sustainable business practices

Maintaining transparent and ongoing communication with stakeholders

Fulfilling our promise to be a trusted steward of legacy nuclear materials

Decommissioning Nuclear Power Plants

Decommissioning is the process by which nuclear power plants are safely retired from service. The progression involves decontaminating the facility to reduce residual radioactivity, dismantling the structures, removing contaminated materials to appropriate disposal facilities and releasing the property for other uses. The owner remains accountable to the NRC until decommissioning has been completed and the agency has terminated its license.

Here’s a brief look at what will occur at Indian Point:

- Indian Point shut down Unit 3, its final operating reactor, on Friday, April 30, at 11:00 p.m. This removed about 1,000 megawatts of electricity from the regional grid.

- Indian Point’s fuel has been removed from the reactor vessel and placed in the spent fuel pool to cool.

- Once cooled, the fuel will be placed in stainless steel canisters and transported to the Independent Spent Fuel Storage Facility (ISFSI) on station property.

- Radioactive equipment and components are dismantled per an approved decommissioning plan.

- Contaminated components are dismantled, securely packaged and transported to a licensed off-site facility.

- The site is inspected by state and federal agencies to ensure the property has been returned to conditions outlined in the decommissioning plans. Both the State and Federal agencies will continue to monitor the site.

Our Decommissioning Team:

After Indian Point Energy Center ceased operations, many of the operations employees transferred into a decommissioning organization. Throughout the decommissioning lifecycle, many of the same employees will assist in the safe dismantlement of Indian Point. Here’s a look at what we will be doing.

Protecting the facility and the public:

A security force will safeguard the facility until all nuclear fuel has been removed from the site.

Engineers, technicians & craftworkers:

A highly qualified, skilled staff of experts will oversee and conduct the entire dismantlement process.

Environmental Scientists:

Using company employees and contracted experts, we will continue a strong environmental monitoring program through decommissioning.

Emergency Responders:

Teams of qualified employees, both on and off-site, will be on-call all day, every day to work to protect the plant in an unlikely emergency situation.

Overview of Decommissioning Process

- To decommission a nuclear power plant, the licensee must submit A Post‐Shutdown Decommissioning Activities Report (PSDAR) to the NRC. This report provides a description of the planned decommissioning activities, a schedule for accomplishing them, and an estimate of the expected costs.

- The licensee has to reduce the residual radioactivity to levels that permit release of the property and termination of the facility’s operating license. The site must be decommissioned within 60 years of the plant ceasing operations.

- The decommissioning process involves removing the used nuclear fuel from the reactor; dismantling systems or components containing radioactive products (e.g. the reactor vessel); and cleaning up or dismantling contaminated materials from the facility.

- Contaminated materials can be disposed of in two ways: decontaminated on site or removed and shipped to a waste processing, storage or disposal facility.

Emergency Planning: Protecting Health and Safety around Indian Point

The nuclear plants at Indian Point have shut down and the nuclear fuel has been removed from the reactors. All of the nuclear fuel has been placed in 180-ton steel and concrete casks on a secure, seismically engineered concrete pad at the site. These casks are designed to withstand natural disasters such as earthquakes, floods and tornadoes. Since the fuel has been placed in long-term storage in the casks, there is no longer any risk of a radiological emergency impacting the 10-mile Emergency Planning Zone.

In 2023, the US Nuclear Regulatory Commission approved the Emergency Plan changes for plant decommissioning that reduced the 10-mile Emergency Planning Zone to the site boundary and also eliminated the need for Emergency Sirens and notifications as there is no longer a radiological risk to the general public. Indian Point maintains emergency procedures commensurate with the risks at the site and performs annual exercises with NY State, two counties, and local offsite response organizations for emergency response to the plant.

The US Nuclear Regulatory Commission oversees the decommissioning process. The spent fuel will remain safe and secure onsite until it is taken away for disposal by the US Department of Energy. Until that time, a robust security program will be maintained at the site.

Decommissioning Options

(Companies can choose one or both options)

SAFSTOR (Safe Storage) ‐ Plant is kept intact, all fuel is placed in spent fuel pool or dry storage casks and time is used as a decontaminating agent. Plant is then dismantled similar to DECON once radioactivity has decayed to lower levels.

DECON (Decontamination) ‐ Contaminated equipment and materials are removed (used nuclear fuel rods and equipment account for over 99 percent of the plant’s radioactivity). Plant is then dismantled ‐ this phase can take five years or longer.

Terminating the NRC License, Releasing the Site

As the DECON phase nears completion, the company must submit a license termination plan to the NRC. This needs to occur within two years of the proposed license termination date. After the NRC receives the license termination plan, affected states, local communities and tribes may submit comments on the plan at a public meeting near the facility. The public also has the opportunity to request an adjudicatory hearing. Members of the public may observe any meeting the NRC holds with the company, unless the discussion involves proprietary, sensitive, safeguarded or classified information.

Once public concerns are addressed, the NRC will terminate the license if all work has followed the approved license termination plan and the final radiation survey shows that the site is suitable for release. Most plans envision releasing the site to the public for unrestricted use, meaning any residual radiation would be below NRC’s limits of 25 millirem per year. This completes the decommissioning process.

Contact Us

HDI is Licensed Operator for Indian Point

Holtec Decommissioning International (HDI) is a wholly owned subsidiary of Holtec International headquartered at the Krishna P. Singh Technology Campus, Camden, NJ. HDI functions as the licensed operator for Holtec owned nuclear power plants. HDI provides licensee oversight of the decommissioning work that is performed.

Emergency Planning

Recent Updates

- Decommissioning Oversight Board (February 12, 2026)

- Decommissioning Oversight Board (December 11, 2025)

- Decommissioning Oversight Board (September 25, 2025)

- Decommissioning Oversight Board (May 1, 2025)

- Decommissioning Oversight Board (December 5, 2024)

- Decommissioning Oversight Board (June 13, 2024)

- Decommissioning Oversight Board (Apr. 25, 2024)

- Decommissioning Oversight Board (Dec. 6, 2023)

- Decommissioning Oversight Board (Sep. 21, 2023)

- IPEC Decommissioning Update (June 15, 2023)

- IPEC Decommissioning Update (Apr. 27, 2023)

- Water Release Fact Sheet

- IPEC Decommissioning Update (Feb. 2, 2023)

- IPEC Decommissioning Update (Dec. 7, 2022)

- IPEC Decommissioning Update (Sept. 22, 2022)

- IPEC Decommissioning Update (July 27, 2022)

- Site VP Rich Burroni Presents to NYS Decommissioning Oversight Board

You must be logged in to post a comment.