We are pleased to announce the shipment of the first state-of-the-art Spent Fuel Storage Racks made of Metamic with the highest reactivity suppression capacity and structural strength metrics to India for deployment at NPCIL’s Kudankulam plant, built with Russian technical collaboration. Kudankulam is a six-unit VVER-1000 plant (KKNPP) located in India’s southern state of Tamil Nadu.

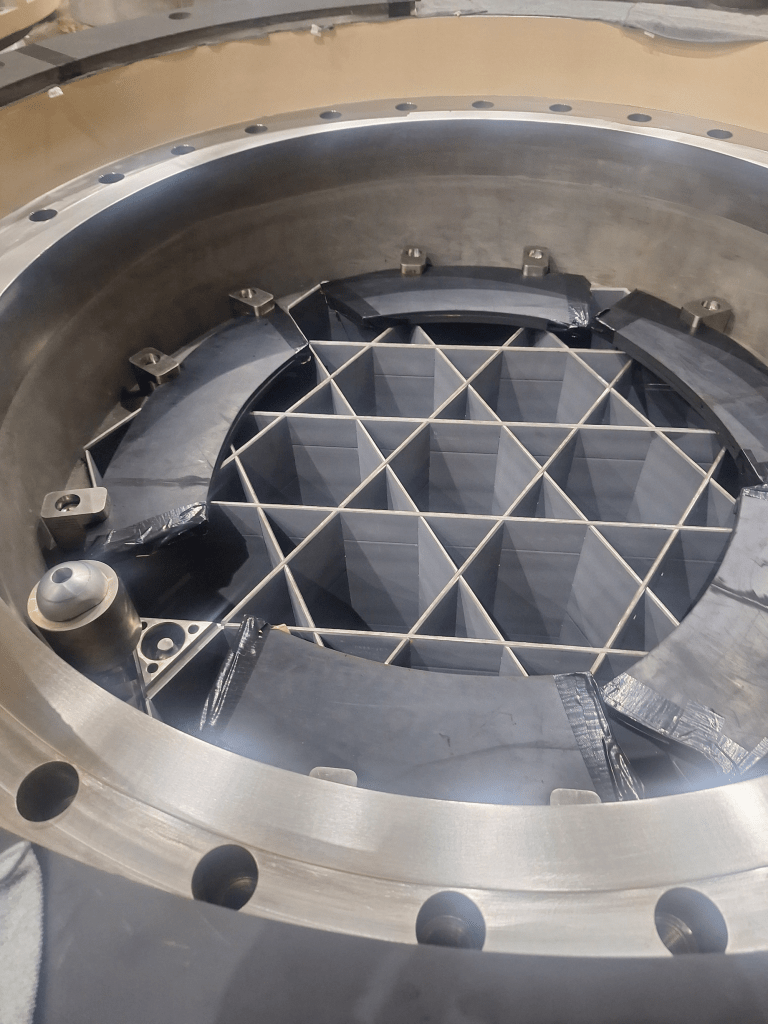

The completed modules, one module pictured on this page, co-produced by Holtec Asia and its parent Holtec International, will be installed in a freestanding configuration in a new wet storage facility being built at the KKNPP site. The hexagonal cross section of the VVER-1000 fuel differentiates from Western Pressurized Water Reactors (PWRs) which are of square cross section.

A separate shipment containing a multi-purpose transport cask, HI-STAR 149, co-produced by Holtec International and Holtec Asia (Pune) featuring the industry’s latest radiation-shielding technology is also headed to India to be used for transferring the spent fuel stored in Kudankulam’s reactor building pools to the wet storage facility.

The rack modules and the transport cask represent the latest in the nuclear criticality safety, radiation blockage and superb structural strength based on several proven Holtec innovations protected by an array of patents that are being introduced to India’s nuclear industry through the above-mentioned equipment. They will form the key equipment needed to execute fuel management operations at KKNPP.

The fuel rack and cask projects, critically important to KKNPP, have been successfully executed by Holtec Asia with the support of its parent, US-based Holtec International. These projects have served as an important vehicle for Holtec International to infuse design, state-of-the-art Quality Assurance and Project Management technologies to Holtec Asia which will help it serve India’s rapidly expanding nuclear program with the latest technical know-how.

The Holtec organization has served as the mainstay of the nuclear industry in the area of densified wet storage of spent nuclear fuel since the 1980s, meeting virtually every nuclear plant’s needs in the West. In the dry storage and transport of used nuclear fuel, Holtec has dominated the sector maintaining an intellectual monopoly enabled by over 250 patents and proprietary technologies. KKNPP is the 148th plant in Holtec’s client roster to use the Company’s cutting-edge spent fuel storage and transport solutions.

You must be logged in to post a comment.