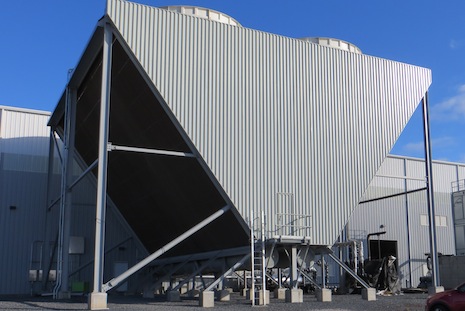

Holtec Asia, an autonomous subsidiary of Holtec International and a globally recognized supplier of state-of-the-art Air-Cooled Condensers (ACCs), announces a significant expansion of its manufacturing facility in Dahej, Gujarat (India) to meet the rising demand for condensing of low-pressure steam produced by power generating and industrial plants without reliance on a cooling water source. Holtec Asia’s cutting-edge manufacturing plant is widely recognized for producing high reliability Air-Cooled Condensers (ACC), which are essential to enable power plants to operate in areas with limited water supply and desirable to prevent thermal pollution of water sources even in locales that are not water-challenged. The Dahej plant (pictured below), formally referred to as the Holtec Asia Advance Manufacturing Division, will become India’s largest ACC fabrication facility when the capacity expansion work effort is completed (scheduled for early March). Along with the near doubling of the output of ACC cells and weldments, certain key subcomponent fabrication capabilities are also being established at the Dahej facility to render it into an autonomous plant with minimal reliance on imports thus insulating the plant from the vagaries of supply chain uncertainties.

Holtec ACCs are available in both forced draft and induced draft configurations, the latter is employed where it is desired to have a shorter silhouette ACC. Both designs have been validated by computational fluid mechanics simulations and by field data from operating units. The Forced draft model is sold under the trade name HI-MAX, and the Induced draft model goes by the name HI-KOOL (representative bundles shown below). Both HI-MAX and HI-KOOL models are known to be highly energy efficient and maintenance-friendly. Innovative design concepts to minimize the noise level in the proximity of the ACC plant is another technical challenge that Holtec Asia’s engineers tackle routinely in their ACC design development effort.

The ongoing expansion of the plant has entailed considerable investment in its infrastructure: the facility has been upgraded with state-of-the-art machinery, new cranes, an oblong tube manufacturing line, and a significantly expanded fabrication space. These enhancements are designed to meet the growing demand for ACC systems from our clients and to reinforce Holtec Asia’s position as a key player in the global power industry.

Holtec Asia’s manufacturing facility adheres to rigorous quality assurance and safety programs that are in full conformance with its parent’s (Holtec International) corporate programs for quality and safety that boast four decades-long track record of impeccable performance. Holtec Asia’s quality program ensures that all products meet the highest standards of quality and operational performance. With this commitment to quality, Holtec Asia endeavours to serve its clients with ACCs that are not only thermally efficient but also supremely reliable, enabling seamless installation and commissioning within the shortest possible timeframes. In the worker safety space, Holtec Asia’s safety metrics, led by Executive Director of Manufacturing, Mr. Amarjit Singh (pictured) are in the top ten percent of heavy equipment fabricators in the country.

“We are pleased to offer the HI-MAX and HI-KOOL ACCs as mature and reliable solutions to replace cooling water with ambient air to condense waste steam from power plants which are voracious consumers of cooling water. We are thankful that industrial plants that are generators of waste steam are some of the most ardent customers of Holtec ACCs. We are gratified that our ACC product line is doing its bit to address the looming crisis of water scarcity that confronts India and the world,” says Dr. Debu Majumdar, Holtec Asia’s Interim President.

You must be logged in to post a comment.