Air-Cooled Condensers

Transformative Air-Cooled Technology

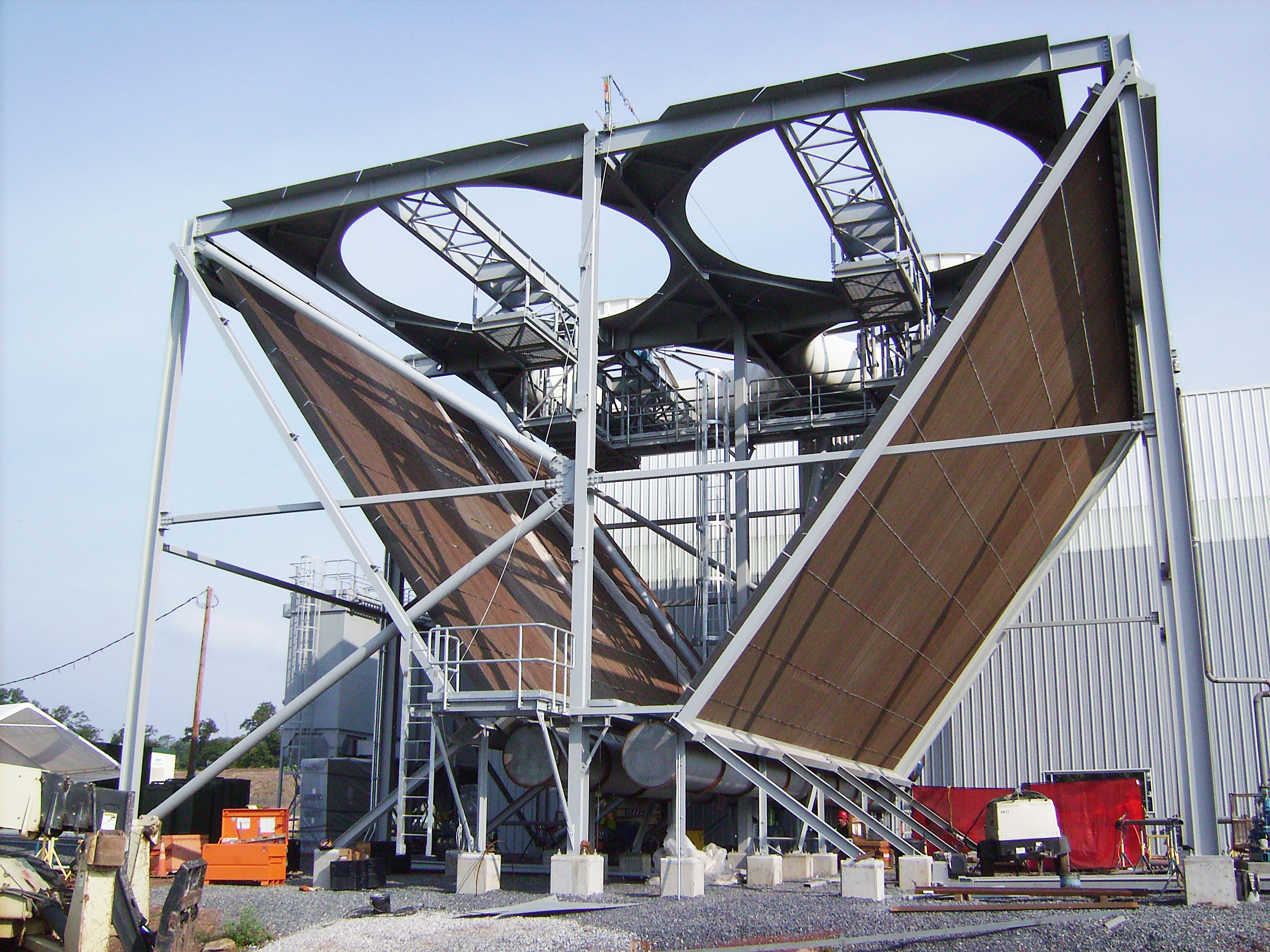

Holtec’s Air-Cooled Condensers represent cutting-edge technology designed to meet the growing global and Indian demand for efficient cooling solutions without relying on water, a precious and increasingly scarce resource. Featuring proprietary HI-MAX and HI-KOOL systems, Holtec’s Air-Cooled Condensers deliver robust performance and reliability across diverse industries, including power, petrochemical, geothermal, and many more.

Key Features

Water Conservation

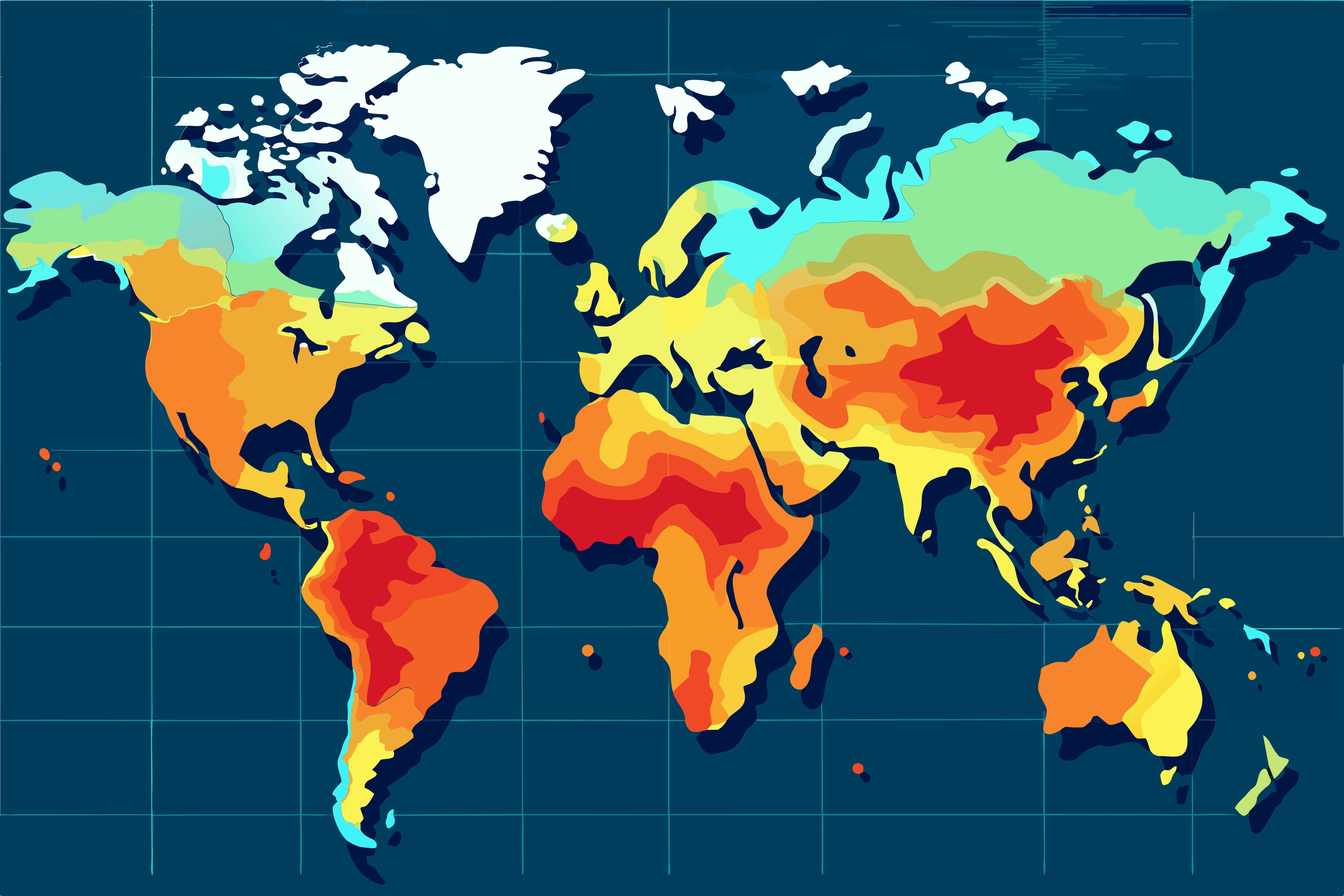

Holtec’s Air-Cooled Condensers systems reduce water usage, addressing critical resource scarcity challenges. This is especially impactful in arid regions where geographical constraints demand innovative solutions.

Self-Supporting Tube Bundles

Holtec’s patented Air-Cooled Condenser design offers modular and stick-built configurations, improving flexibility, reducing construction costs, and providing efficient, scalable cooling solutions.

Customizable and Modular Solutions

Holtec’s Air-Cooled Condensers modular design significantly reduces on-site construction times and costs. Pre-assembled cells can be installed at grade and lifted into place, minimizing the need for elevated work.

Parallel Condensing Capability

Holtec’s expertise in water-cooled and air-cooled systems enables parallel condensing solutions, offering benefits like improved performance in high ambient conditions, capital cost savings, and substantial water conservation.

Induced-Draft Cooling

Engineered for maximum reliability and efficiency, HI-MAX and HI-KOOL systems incorporate obround tubes with high-performance aluminum fins and innovative induced-draft cooling mechanisms.

Innovations Driving the Market

HI-MAX

HI-MAX’s finned metallic obround tubes integrate into a fully modularized structure for easy assembly. Strength-bonded aluminum fins ensure long service life and condensate purity. Advanced computational fluid dynamics codes optimize fin thickness, height and spacing and provide maximum air flow efficiency.

HI-KOOL

HI-KOOL transforms the technology that rejects waste heat to ambient air. Coolant ambient air is pulled across obround finned tubes by an overhead blower, extracting latent heat from low-pressure steam flowing inside the tubes. HI-KOOL’s enhanced, low-profile design allows for ease of construction, reducing assembly times.

Proven Track Record and Manufacturing Excellence

55+

Air-Cooled Condenser installations in India and overseas.

2,000+

Tube bundles produced by Holtec Asia every year.

0

Performance or operational issues post-commissioning.

Manufacturing Facilities

Holtec Asia leads the industry with proven expertise in delivering precision complete Air-Cooled Condenser packages and components. Its plant produces over 2,000 tube bundles annually, for domestic and international markets.

State-of-the-Art Engineering Tools

Holtec Asia’s in-house thermo-hydraulic design program, through its engineers and specialists, ensures precise performance prediction, integrating Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and Dynamic Structural Analysis.

Addressing the Growing Global and Indian Demand

The demand for Air-Cooled Condenser systems is surging globally, driven by geographical challenges such as water scarcity in arid regions like the Middle East and evolving environmental regulations. India’s thermal power sector is witnessing steady growth, driven by major initiatives such as the installation of new generating units and the conversion of water-cooled condensers to air-cooled condenser (ACC) systems. Holtec Asia is actively supporting this transition by supplying complete ACC packages and tube bundles to leading EPC contractors and end users.

Why Holtec Asia’s Air-Cooled Condensers?

- Induced draft air-cooled condensers are often preferred for applications requiring a lower profile, reduced visual impact, and smaller footprint compared to forced draft designs. They are also favored for their ability to handle variable loads and for their energy efficiency in certain situations.

- HI-MAX and HI-KOOL are both validated through computational fluid dynamics simulations and real-world performance data, ensuring high energy efficiency and low maintenance requirements.

- Holtec Asia integrates innovative noise-reduction techniques into its Air-Cooled Condensers to enhance plant surroundings.

- The global demand for Air-Cooled Condensers is increasing due to tightening environmental regulations and water scarcity in arid regions like the Middle East.

- To meet growing demand, Holtec Asia has expanded its state-of-the-art manufacturing facility in Dahej, Gujarat. This facility is renowned for producing premium finned tube bundles, which are crucial for sustainable power plant cooling systems that eliminate water dependence.

- Once completed, the Dahej plant—formally known as the Holtec Asia Advanced Manufacturing Division—will be India’s largest Air-Cooled Condenser fabrication facility. The expansion will nearly double Air-Cooled Condenser cell and weldment output, while integrating key subcomponent manufacturing to reduce import reliance, mitigating supply chain risks and ensuring greater production autonomy.

Vision for Growth

With a clear focus on innovation and sustainability, Holtec Asia continues to expand its footprint, supporting global efforts to reduce water dependency through its state-of-the-art Air-Cooled Condenser designs while meeting rising energy demands. The company’s unwavering commitment to excellence reinforces its leadership position in the Air-Cooled Condenser market for years to come.

You must be logged in to post a comment.