The power output from power plants that rely on cooling water from proximate bodies of water, such as a lake, sea, or river, has been steadily eroding as their bulk temperature inches upwards because of global warming. The temperature of Lake Michigan, which supplies cooling water to Holtec Palisades nuclear plant currently undergoing refurbishment and upgrades, has been ticking up like the rest of the world’s water reservoirs and is expected to continue rising in the coming decades during its projected service life.

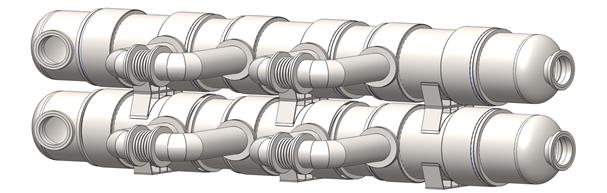

We are pleased to report that, as a part of the ongoing melioration of the Palisades nuclear plant, Holtec has successfully developed an innovative embodiment of the plant’s cooling water heat exchanger system that is being manufactured at Holtec’s own fabrication plant (the Holtec Manufacturing Division) in Pittsburgh, PA.

The main challenge in this system’s development was the extremely congested space where the existing unit is located (typical of power plants). To meet the projected rising lake water temperature, the new unit needed to be more than twice as large in heat transfer surface area as the existing unit, but had to fit in the same space. “It was like asking to put two gallons of milk in a one-gallon carton,” said Edward Bell, Director of Holtec’s Heat Transfer Division. The upgraded heat exchanger set will be installed within the next 12 months to support the 2025 year-end repowering of Palisades. Thanks to its innovative design, this cooling system upgrade will require very little civil/structural work, which may reduce the project cost by over 50% compared to the initial projection.

“We are pleased to report this technical achievement to the industry to make other plant developers aware of what is possible to combat the adverse effect of global warming on nuclear and other power plants,” said Joy Russell, Holtec’s Chief Communications Officer.

You must be logged in to post a comment.