Neutron Absorber Material

Transformative Technology

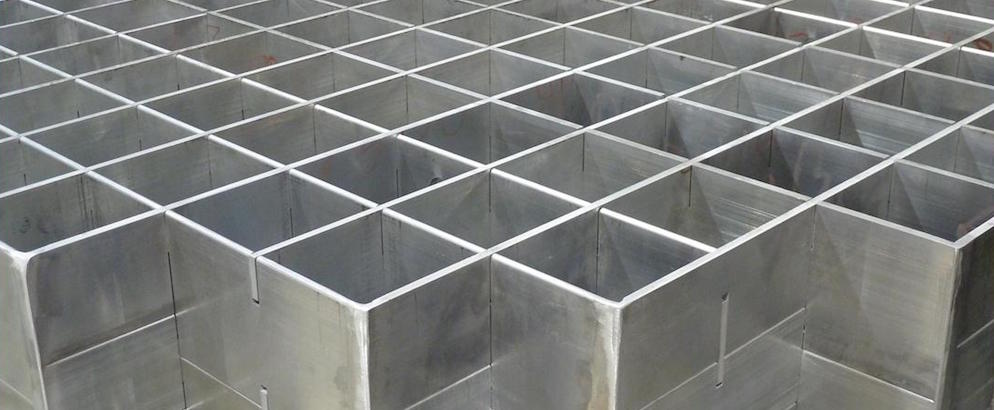

The Neutron Absorber Material is at the heart of used fuel storage and transport devices such as fuel racks and dry storage casks. Metamic is a fully dense, homogenous material that has a proven record as a stable, non-porous material in aqueous environments. To ensure product quality appropriate to a safety-related part, Holtec runs its own rigorous laboratory test program to confirm the critical characteristics of the neutron absorber.

Why Metamic?

- Metamic™ is approved by the USNRC, KINS, and numerous other nuclear regulatory authorities for both wet and dry storage applications.

- Metamic™ radiation shielding products are fabricated using powder metallurgy technology from nuclear grade boron carbide (ASTM C750 Type 1) and high-purity aluminum powder.

- Metamic-HT™ is the first nanotechnology-based material to gain USNRC approval (ca. 2008) as both a structural and neutron absorption material for use in the fuel basket of a Holtec’s HI-STAR 180 transport cask (Docket No. 71-9325).

- Metamic-HT™ is the licensed structural and neutron absorber material of Holtec’s high capacity multi-purpose canister baskets.

Innovations Driving the Market

Metamic™ Classic

Metamic™ Classic is a discontinuously reinforced aluminum boron carbide metal matrix composite material designed for neutron radiation shielding applications. Metamic™ offers advantages over other neutron absorbers, including no swelling in any spent fuel storage environment, no risk of hydrogen ignition during dry storage, remains structurally sound under neutron and gamma fluences and has excellent structural properties.

Metamic-HT™

Metamic-HT™ is a high temperature aluminum boron carbide metal matrix composite material. It has excellent physical properties at elevated and cryogenic temperatures, including excellent creep resistance, yield strength, tensile strength and fracture toughness. This powder metallurgy technology produces an extremely fine-grained nano-particle alumina reinforced matrix alloy with boron carbide particulate addition to form a metal matrix composite alloy system.

Rigorous Protocols

In recognition of the central role of the neutron absorber in maintaining subcriticality, Holtec utilizes appropriately rigorous technical and quality assurance criteria and acceptance protocols to ensure satisfactory neutron absorber performance over the service life of the fuel racks, casks and canisters. Our Quality Assurance Program ensures that Metamic™ is manufactured under control and surveillance of that conforms to the requirements of 10CFR50 Attachment I, “Quality Assurance Criteria for Nuclear Power Plants.”

You must be logged in to post a comment.