Innovative Technologies

Holtec International develops innovative, cost-effective solutions that help clients overcome complex technical challenges. When unique issues arise, Holtec’s engineers design safe and practical approaches that work within plant constraints, providing flexible alternatives that often avoid costly modifications or upgrades.

Innovations Driving the Market

HI-TRAN Heavy Load Hauler

Holtec’s HI-TRAN (Holtec International Transporter) is a vertical heavy load hauler for dry spent fuel storage system components and execution of inter-cask canister transfer.

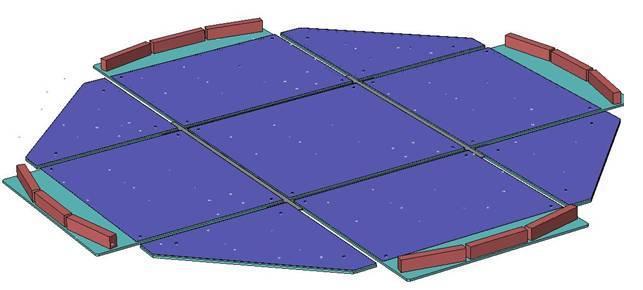

Neutron Absorber Material

Holtec‘s Metamic-HT is a dual-purpose structural and neutron-absorbing material used in MPC baskets, high-density racks, and DREAM inserts to maintain criticality margins.

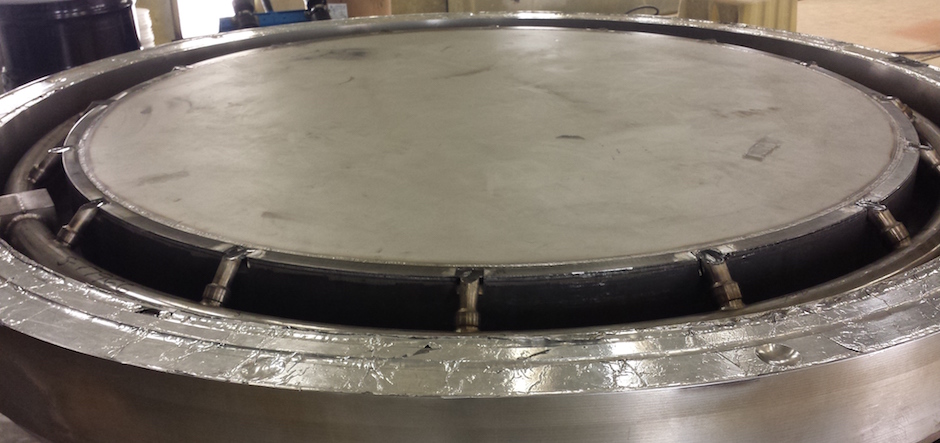

Forced Helium Dehydrator

Holtec’s Forced Helium Dehydrator (FHD), an alternative to the vacuum dryer, is employed by more than 20 nuclear units worldwide, including Chernobyl and Sizewell B.

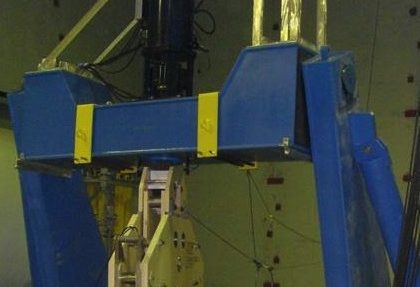

HI-LIFT

Holtec’s HI-LIFT system leverages the fuel pool walls and adjacent slab to support and handle a loaded cask in structurally challenged enclosure buildings.

HERMIT

HERMIT (Holtec Earthquake Response Mitigator) allows cask loading operations to proceed without physically tie-downs for seismic protection.

Variable Elevation Cask Pedestal

Holtec’s VECASP device eliminates the root cause of crane contamination by preventing pool water from wetting the crane block and its associated components.

Holtite™ Neutron Shield

Holtite™ is Holtec’s proprietary neutron-shielding material, first used in HI-STAR 100 casks and now standard in our transport, transfer, and ventilated storage systems. Made from a hydrogen-rich polymer with boron carbide, Holtite™ is available in multiple formulations tailored to temperature and thermal conductivity needs and can be applied to any nuclear system requiring neutron capture, including reprocessing and enrichment facilities.

Zero Profile Transporter (ZPT)

Holtec’s Zero Profile Transporter (ZPT) enables loaded HI-STORM and HI-TRAC casks to move through a plant’s truck bay while staying extremely close to the floor. This “zero-height dolly” requires only minimal door clearance—just slightly more than the cask height. Because truck-bay transport offers ALARA benefits and easier handling, many plants face roll-up door height limits. The ZPT overcomes this constraint by allowing safe, low-clearance movement of loaded casks.

Reverse Engineered Components

Holtec provides complete in-house capabilities to design, fabricate, and deliver replacement SSCs, including those no longer supported by the original OEM or based on obsolete technology. We offer custom fabrication and a proven record of meeting outage-critical schedules. We also supply reverse-engineered components that enhance or modernize existing equipment. Our integrated supply chain sources all required materials to keep fabrication on track.

You must be logged in to post a comment.