Green Boiler

An Omni-Purpose Thermal Storage & Steam Supply System

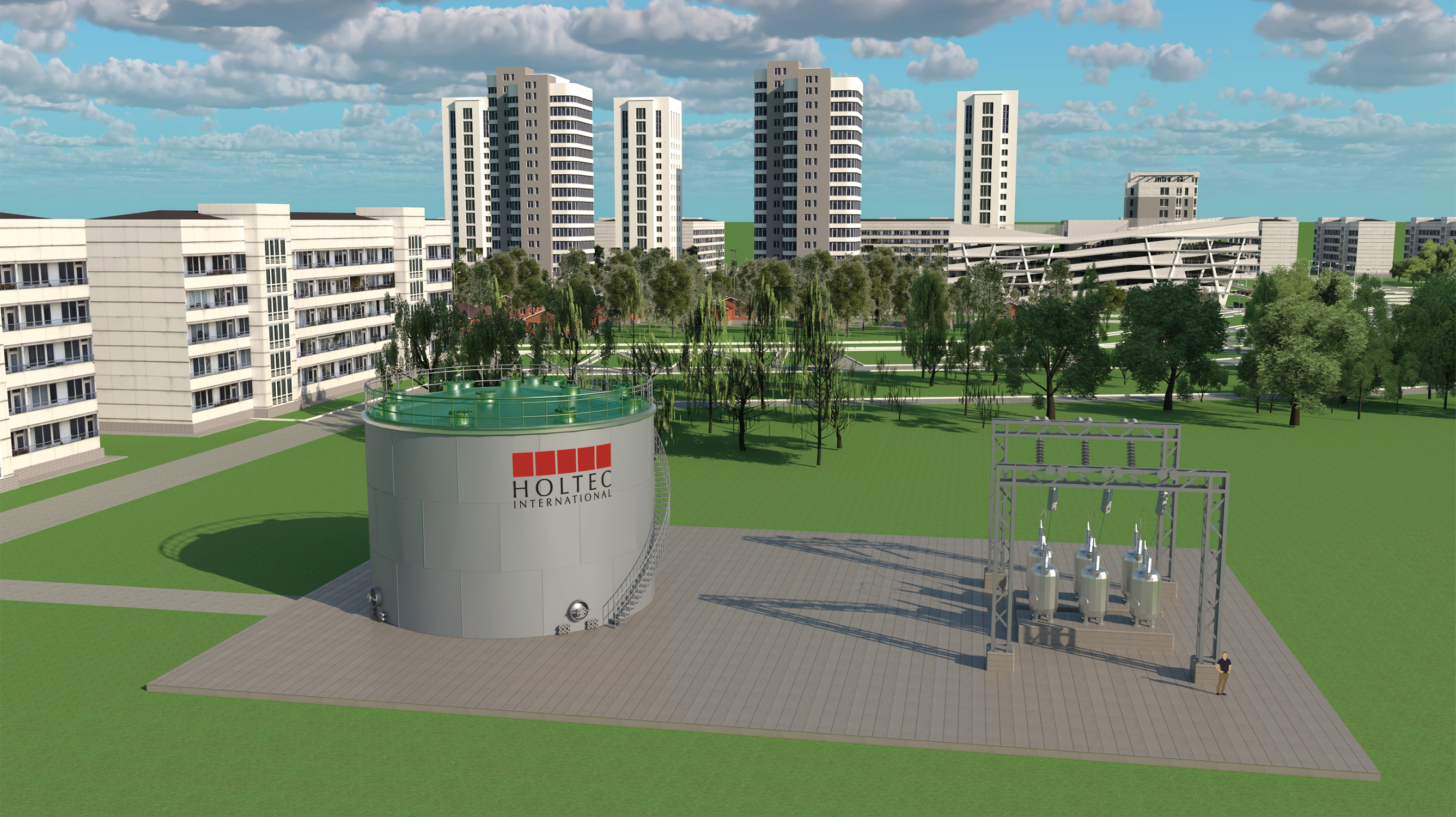

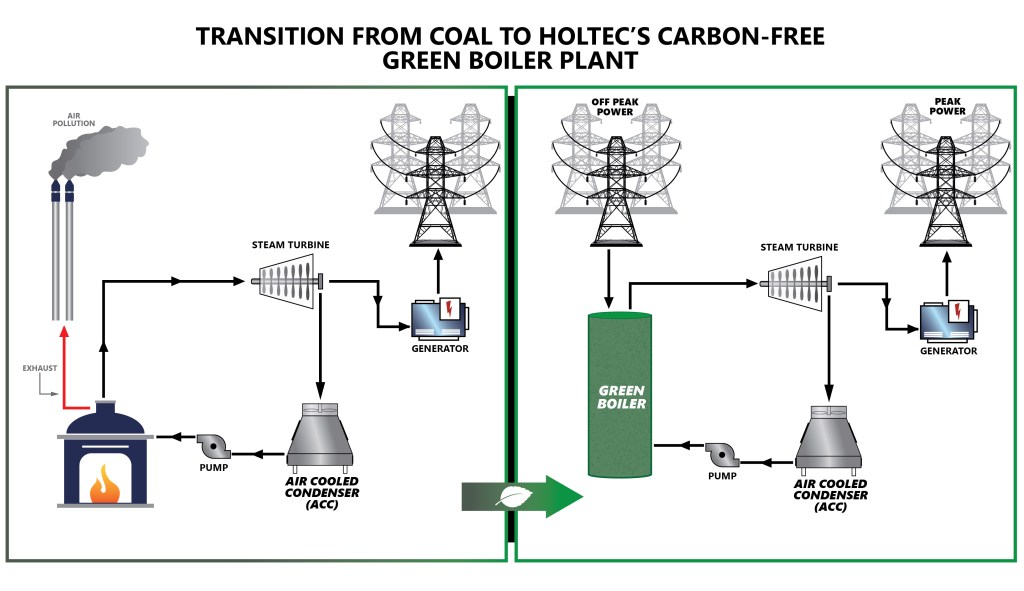

Coal-fired plants are economic anchors for their communities, providing jobs and supporting local tax bases. As climate policies drive their closure, these communities face severe disruption. Green Boiler technology enables the conversion of coal plants to clean energy facilities, preserving many jobs and reusing most existing infrastructure, excluding coal-specific systems.

Key Features

- The Green Boiler components are sized to be shop manufactured and shipped by land or sea.

- The standard design target used to size the Green Boiler vessels is 12 hours at full power. This on-power duration can be increased, if necessary, for a particular application

- Energy can be stored for long periods with little parasitic loss to the ambient.

- The storage system is modular; the energy storage capacity is theoretically limitless because there is no limit on the number of modules that can be arrayed at a site.

- All or a portion of the steam from the Green Boiler can be diverted to serve as process steam for other industrial applications such as making the hydrogen fuel.

- The Green Boiler does not use any rare materials; all materials can be sourced domestically in any industrial country.

- Unlike batteries, the Green Boiler does not have a finite cycle life. No part of the Green Boiler suffers from a discernible rate of service life expenditure.

- Unlike Li-ion batteries, the Green Boiler is not vulnerable to fire.

- Green Boiler’s capital cost is competitive with a battery installation; It has an incomparably longer service life (ie, period of depreciation).

- Roughly speaking, about 2 sq. ft. of land is needed to store each MWH of thermal energy (land use is proportional to the quantity of energy stored).

- The Green Boiler installation should be sheltered from rain, wind or snow for optimum performance.

The Green Boiler system is essentially a large thermal reservoir filled with engineered salts spiked with infrared emitter particles or a highly conductive elemental metal. The Green Boiler stores the surplus (inexpensive) power from the grid and uses the stored thermal energy to run the existing plant’s turbogenerator to produce electricity on demand.

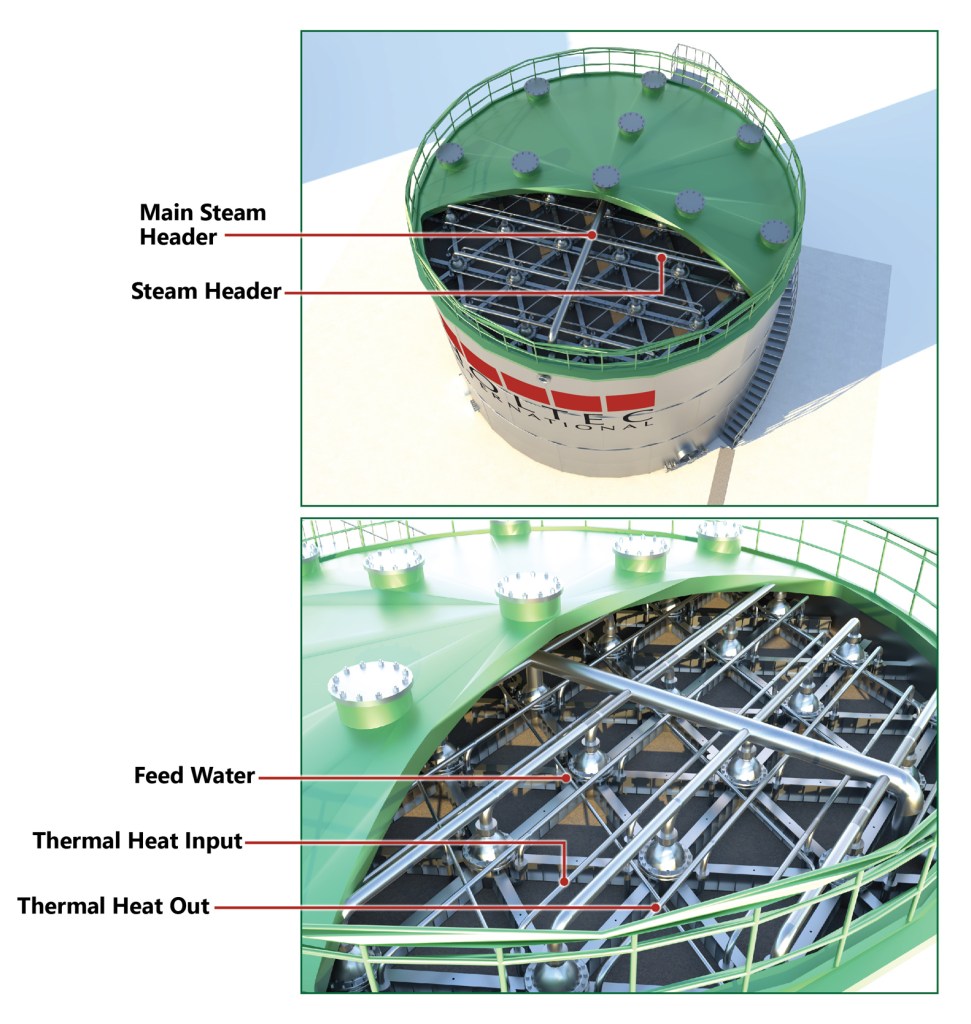

Each Green Boiler module consists of three large cylindrical vessels substantially filled with engineered salts (hereafter called the “Thermal Repository”) and equipped with specially configured tubes to convert feed water into superheated steam. The three vessels are referred to as the pre-heater, the boiler and the superheater, respectively. Each vessel is heavily insulated to limit the loss of heat to the ambient to minuscule values. Each vessel contains a tube bundle configured to permit significant expansion and contraction during the plant’s operation without significant cyclic fatigue and withstand solidification of the enveloping Thermal Repository as its heat is delivered to produce cycle steam. Another essential feature is the extremely corrosive molten Thermal Repository (TR) material remains stationary in each vessel: It delivers its heat to the water circulating in the tubes imbedded in the TR space through radiation and conduction action depending on the thermophysical properties of the TR material. Each vessel is evacuated of air and backfilled with an inert gas to mitigate oxidation of the TR material and corrosion of the tubes. The inside space of the Green Boiler vessels are engineered to be amenable to convenient maintenance and repair, if required.

This version of the Green Boiler is expressly focused to re-purpose the retiring coal-fired plants. The development of another embodiment is underway that would employ a high efficiency power cycle for the Green Boiler and conjugate it with Holtec’s SMR-300 and/or with a solar collection system to help align supply to the power demand of the grid. With the Green Boiler at the center, a viable local energy ecosystem can be developed to provide electricity, process steam and/or hydrogen in proper proportion to serve the local economy.

You must be logged in to post a comment.