We are pleased to announce the successful completion of the loading operation, where Holtec International’s Global Site Services Unit, with able support from our associates from Holtec Do Brasil, transferred used fuel from Electronuclear’s Angra Unit 2 plant into our HI-STORM FW dry storage overpacks. The loading campaign, which involved placing 480 used nuclear fuel assemblies into 15 HI-STORM FW dry storage casks, was finished ahead of schedule and without injuries or human performance errors during completion of this project.

The HI-STORM systems contained MPC-32ML a multi-purpose canister, which features a specially designed and licensed Metamic-HT fuel basket optimized for the unique Angra 2 fuel. Holtec’s team will return to Angra 1 site to load 18 HI-STORM FW systems with 75 damaged fuel containers in early 2025. Angra 1 used fuel will be stored in HI-STORM FW system containing MPC-37 canisters, each storing 37 PWR spent fuel assemblies.

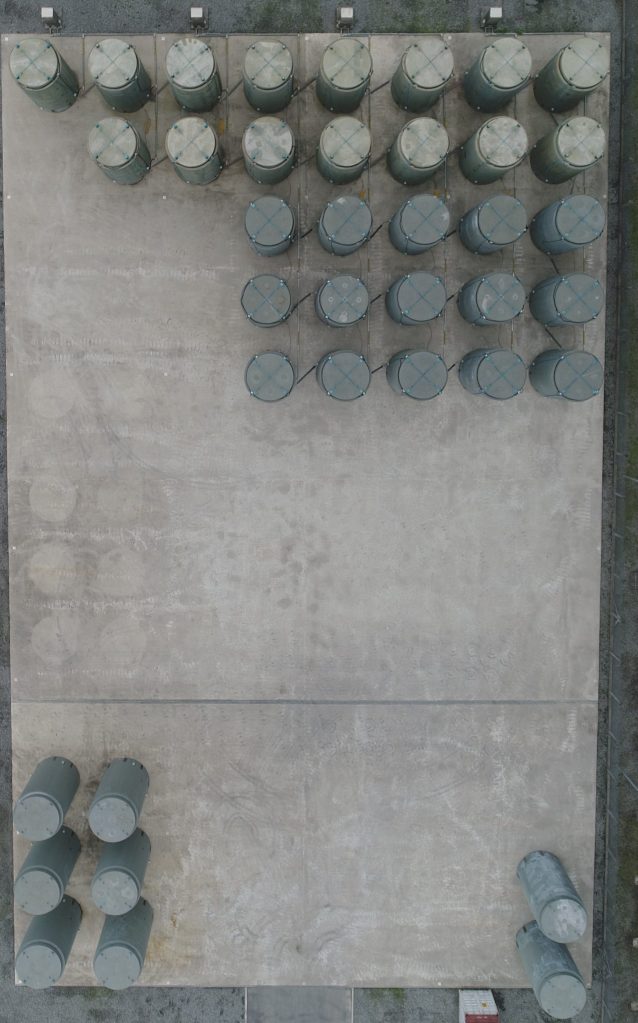

Under a Client-Assisted Turnkey contract signed in 2017, Holtec designed and built the dry storage infrastructure, which included construction of the Complementary Dry Storage Unit for Spent Fuel ISFSI pad as well as modification of the plant cask handling cranes and equipment to facilitate loading and storage of casks at Angra Unit 1 and 2. During the previous loading campaigns in the years 2021-2022, Holtec successfully loaded 15 casks to store used fuel from both Angra units. At the conclusion of the upcoming Angra 1 campaign, a total of 48 HI-STORM systems will be in storage at the Angra nuclear station.

As part of this year’s cask loading campaign for Unit 2, the company deployed its state-of-the-art Holtec International Fuel Repair Device (FRD) technology to repair 125 damaged spent fuel assemblies. The FRD technology renders a damaged fuel assembly that cannot be handled by normal means into one that can be handled in a normal manner using the plant’s existing fuel handling tooling. As is well known in the industry, certain types of PWR fuel assemblies suffer from the top nozzle separation issue caused by the intergranular stress corrosion cracking damage, which makes them structurally-incompetent to allow their handling, hampering the plant’s ability to return them to the reactor core or move them into dry storage. FRD is the only fuel repair technology available in the industry that involves no welding or introduction of any foreign material in the fuel pool.

Holtec first employed the innovative FRD technology at its Indian Point Nuclear plant during the plant’s last defueling campaign about a year ago.

“I am writing to express my sincere gratitude for the exceptional work carried out by Holtec during the loading campaign of Angra 2. The dedication, attention to detail, and commitment to excellence did not go unnoticed. The effort put forth by Holtec team was crucial in helping us achieve our objectives, ensuring safety, maintaining quality, and meeting deadlines. I truly appreciate the positive attitude demonstrated by your team,” wrote Fabiano Portugal, Angra Unit 2 Plant Manager, Electronuclear in a letter to Holtec.

“We thank Electronuclear team for their exemplary support for the Angra 2 used fuel storage campaign. We are gratified to see our innovative spent fuel storage solutions play a critical role at the Angra Nuclear Station. We look forward to a repeat success when our team returns to load used fuel at Angra 1 in early 2025” said PK Chaudhary, President of Holtec’s Nuclear Power Division with direct responsibility for Projects, Manufacturing & Supply Chain.

You must be logged in to post a comment.